Rolling

We have always made chips.

Then we decided to add other things.

| Token | Value |

|---|---|

| [node:author] | david |

| [node:author:account-name] | david |

| [node:author:created] | Thu, 06/27/2019 - 16:47 |

| [node:author:created:fallback] | Thu, 06/27/2019 - 16:47 |

| [node:author:created:html_date] | 2019-06-27 |

| [node:author:created:html_datetime] | 2019-06-27T16:47:42+0200 |

| [node:author:created:html_month] | 2019-06 |

| [node:author:created:html_time] | 16:47:42 |

| [node:author:created:html_week] | 2019-W26 |

| [node:author:created:html_year] | 2019 |

| [node:author:created:html_yearless_date] | 06-27 |

| [node:author:created:long] | Thursday, June 27, 2019 - 16:47 |

| [node:author:created:medium] | Thu, 06/27/2019 - 16:47 |

| [node:author:created:raw] | 1561646862 |

| [node:author:created:short] | 06/27/2019 - 16:47 |

| [node:author:created:since] | 3 years 8 months |

| [node:author:name] | david |

| [node:author:display-name] | david |

| [node:author:edit-url] | https://www.montesi.it/it/user/15/edit |

| [node:author:mail] | david@weevo.it |

| [node:author:last-login] | Fri, 11/25/2022 - 08:17 |

| [node:author:last-login:fallback] | Fri, 11/25/2022 - 08:17 |

| [node:author:last-login:html_date] | 2022-11-25 |

| [node:author:last-login:html_datetime] | 2022-11-25T08:17:23+0100 |

| [node:author:last-login:html_month] | 2022-11 |

| [node:author:last-login:html_time] | 08:17:23 |

| [node:author:last-login:html_week] | 2022-W47 |

| [node:author:last-login:html_year] | 2022 |

| [node:author:last-login:html_yearless_date] | 11-25 |

| [node:author:last-login:long] | Friday, November 25, 2022 - 08:17 |

| [node:author:last-login:medium] | Fri, 11/25/2022 - 08:17 |

| [node:author:last-login:raw] | 1669360643 |

| [node:author:last-login:short] | 11/25/2022 - 08:17 |

| [node:author:last-login:since] | 3 months 2 weeks |

| [node:author:roles] | authenticated, administrator |

| [node:author:roles:count] | 2 |

| [node:author:roles:first] | authenticated |

| [node:author:roles:join-path] | authenticated/administrator |

| [node:author:roles:keys] | authenticated, administrator |

| [node:author:roles:keys:count] | 2 |

| [node:author:roles:keys:first] | authenticated |

| [node:author:roles:keys:join-path] | authenticated/administrator |

| [node:author:roles:keys:last] | administrator |

| [node:author:roles:keys:reversed] | administrator, authenticated |

| [node:author:roles:last] | administrator |

| [node:author:roles:reversed] | administrator, authenticated |

| [node:author:roles:reversed:count] | 2 |

| [node:author:roles:reversed:first] | administrator |

| [node:author:roles:reversed:join-path] | administrator/authenticated |

| [node:author:roles:reversed:keys] | administrator, authenticated |

| [node:author:roles:reversed:last] | authenticated |

| [node:author:url] | https://www.montesi.it/it/user/15 |

| [node:author:url:absolute] | https://www.montesi.it/it/user/15 |

| [node:author:url:args] | , user, 15 |

| [node:author:url:args:count] | 2 |

| [node:author:url:args:first] | user |

| [node:author:url:args:join-path] | user/15 |

| [node:author:url:args:keys] | 0, 1 |

| [node:author:url:args:last] | 15 |

| [node:author:url:args:reversed] | 15, user |

| [node:author:url:brief] | www.montesi.it/it/user/15 |

| [node:author:url:path] | /user/15 |

| [node:author:url:relative] | /it/user/15 |

| [node:author:url:unaliased] | https://www.montesi.it/it/user/15 |

| [node:author:url:unaliased:absolute] | https://www.montesi.it/it/user/15 |

| [node:author:url:unaliased:args] | , user, 15 |

| [node:author:url:unaliased:brief] | www.montesi.it/it/user/15 |

| [node:author:url:unaliased:path] | /user/15 |

| [node:author:url:unaliased:relative] | /it/user/15 |

| [node:author:uid] | 15 |

| [node:author:role-ids] | 0,1 |

| [node:author:role-names] | authenticated,administrator |

| [node:field_banner] |

|

| [node:field_banner:crop_200x200] | https://www.montesi.it/sites/default/files/styles/crop_200x200/public/banner/rullatura.jpg?itok=LJ7C4S79 |

| [node:field_banner:crop_200x200:filesize] | 7203 |

| [node:field_banner:crop_200x200:height] | 133 |

| [node:field_banner:crop_200x200:mimetype] | image/jpeg |

| [node:field_banner:crop_200x200:uri] | public://styles/crop_200x200/public/banner/rullatura.jpg |

| [node:field_banner:crop_200x200:url] | https://www.montesi.it/sites/default/files/styles/crop_200x200/public/banner/rullatura.jpg?itok=LJ7C4S79 |

| [node:field_banner:crop_200x200:width] | 200 |

| [node:field_banner:crop_470x270] | https://www.montesi.it/sites/default/files/styles/crop_470x270/public/banner/rullatura.jpg?itok=UlB-qZDa |

| [node:field_banner:crop_470x270:filesize] | 26025 |

| [node:field_banner:crop_470x270:height] | 313 |

| [node:field_banner:crop_470x270:mimetype] | image/jpeg |

| [node:field_banner:crop_470x270:uri] | public://styles/crop_470x270/public/banner/rullatura.jpg |

| [node:field_banner:crop_470x270:url] | https://www.montesi.it/sites/default/files/styles/crop_470x270/public/banner/rullatura.jpg?itok=UlB-qZDa |

| [node:field_banner:crop_470x270:width] | 470 |

| [node:field_banner:crop_570x380] | https://www.montesi.it/sites/default/files/styles/crop_570x380/public/banner/rullatura.jpg?itok=pvKAJ9di |

| [node:field_banner:crop_570x380:filesize] | 34852 |

| [node:field_banner:crop_570x380:height] | 380 |

| [node:field_banner:crop_570x380:mimetype] | image/jpeg |

| [node:field_banner:crop_570x380:uri] | public://styles/crop_570x380/public/banner/rullatura.jpg |

| [node:field_banner:crop_570x380:url] | https://www.montesi.it/sites/default/files/styles/crop_570x380/public/banner/rullatura.jpg?itok=pvKAJ9di |

| [node:field_banner:crop_570x380:width] | 570 |

| [node:field_banner:crop_1200x500] | https://www.montesi.it/sites/default/files/styles/crop_1200x500/public/banner/rullatura.jpg?h=1c5b1964&itok=yJnfMnk6 |

| [node:field_banner:crop_1200x500:filesize] | 78988 |

| [node:field_banner:crop_1200x500:height] | 500 |

| [node:field_banner:crop_1200x500:mimetype] | image/jpeg |

| [node:field_banner:crop_1200x500:uri] | public://styles/crop_1200x500/public/banner/rullatura.jpg |

| [node:field_banner:crop_1200x500:url] | https://www.montesi.it/sites/default/files/styles/crop_1200x500/public/banner/rullatura.jpg?h=1c5b1964&itok=yJnfMnk6 |

| [node:field_banner:crop_1200x500:width] | 1200 |

| [node:field_banner:crop] | https://www.montesi.it/sites/default/files/styles/crop/public/banner/rullatura.jpg?h=629a1ba2&itok=TiDlspg9 |

| [node:field_banner:crop:filesize] | 79770 |

| [node:field_banner:crop:height] | 400 |

| [node:field_banner:crop:mimetype] | image/jpeg |

| [node:field_banner:crop:uri] | public://styles/crop/public/banner/rullatura.jpg |

| [node:field_banner:crop:url] | https://www.montesi.it/sites/default/files/styles/crop/public/banner/rullatura.jpg?h=629a1ba2&itok=TiDlspg9 |

| [node:field_banner:crop:width] | 1400 |

| [node:field_banner:entity] | rullatura.jpg |

| [node:field_banner:entity:basename] | rullatura.jpg |

| [node:field_banner:entity:changed] | Fri, 02/14/2020 - 18:55 |

| [node:field_banner:entity:changed:fallback] | Fri, 02/14/2020 - 18:55 |

| [node:field_banner:entity:changed:html_date] | 2020-02-14 |

| [node:field_banner:entity:changed:html_datetime] | 2020-02-14T18:55:14+0100 |

| [node:field_banner:entity:changed:html_month] | 2020-02 |

| [node:field_banner:entity:changed:html_time] | 18:55:14 |

| [node:field_banner:entity:changed:html_week] | 2020-W07 |

| [node:field_banner:entity:changed:html_year] | 2020 |

| [node:field_banner:entity:changed:html_yearless_date] | 02-14 |

| [node:field_banner:entity:changed:long] | Friday, February 14, 2020 - 18:55 |

| [node:field_banner:entity:changed:medium] | Fri, 02/14/2020 - 18:55 |

| [node:field_banner:entity:changed:raw] | 1581702914 |

| [node:field_banner:entity:changed:short] | 02/14/2020 - 18:55 |

| [node:field_banner:entity:changed:since] | 3 years |

| [node:field_banner:entity:created] | Fri, 02/14/2020 - 18:55 |

| [node:field_banner:entity:created:fallback] | Fri, 02/14/2020 - 18:55 |

| [node:field_banner:entity:created:html_date] | 2020-02-14 |

| [node:field_banner:entity:created:html_datetime] | 2020-02-14T18:55:14+0100 |

| [node:field_banner:entity:created:html_month] | 2020-02 |

| [node:field_banner:entity:created:html_time] | 18:55:14 |

| [node:field_banner:entity:created:html_week] | 2020-W07 |

| [node:field_banner:entity:created:html_year] | 2020 |

| [node:field_banner:entity:created:html_yearless_date] | 02-14 |

| [node:field_banner:entity:created:long] | Friday, February 14, 2020 - 18:55 |

| [node:field_banner:entity:created:medium] | Fri, 02/14/2020 - 18:55 |

| [node:field_banner:entity:created:raw] | 1581702914 |

| [node:field_banner:entity:created:short] | 02/14/2020 - 18:55 |

| [node:field_banner:entity:created:since] | 3 years |

| [node:field_banner:entity:extension] | jpg |

| [node:field_banner:entity:size-raw] | 211645 |

| [node:field_banner:entity:fid] | 376 |

| [node:field_banner:entity:name] | rullatura.jpg |

| [node:field_banner:entity:size] | 206.68 KB |

| [node:field_banner:entity:mime] | image/jpeg |

| [node:field_banner:entity:owner] | david |

| [node:field_banner:entity:owner:account-name] | david |

| [node:field_banner:entity:owner:created] | Thu, 06/27/2019 - 16:47 |

| [node:field_banner:entity:owner:name] | david |

| [node:field_banner:entity:owner:display-name] | david |

| [node:field_banner:entity:owner:edit-url] | https://www.montesi.it/en/user/15/edit |

| [node:field_banner:entity:owner:mail] | david@weevo.it |

| [node:field_banner:entity:owner:last-login] | Fri, 11/25/2022 - 08:17 |

| [node:field_banner:entity:owner:roles] | authenticated, administrator |

| [node:field_banner:entity:owner:url] | https://www.montesi.it/en/user/15 |

| [node:field_banner:entity:owner:uid] | 15 |

| [node:field_banner:entity:owner:role-ids] | 0,1 |

| [node:field_banner:entity:owner:role-names] | authenticated,administrator |

| [node:field_banner:entity:path] | public://banner/rullatura.jpg |

| [node:field_banner:entity:url] | https://www.montesi.it/sites/default/files/banner/rullatura.jpg |

| [node:field_banner:target_id] | 376 |

| [node:field_banner:height] | 1333 |

| [node:field_banner:large] | https://www.montesi.it/sites/default/files/styles/large/public/banner/rullatura.jpg?itok=0xaUqNbb |

| [node:field_banner:large:filesize] | 26598 |

| [node:field_banner:large:height] | 320 |

| [node:field_banner:large:mimetype] | image/jpeg |

| [node:field_banner:large:uri] | public://styles/large/public/banner/rullatura.jpg |

| [node:field_banner:large:url] | https://www.montesi.it/sites/default/files/styles/large/public/banner/rullatura.jpg?itok=0xaUqNbb |

| [node:field_banner:large:width] | 480 |

| [node:field_banner:linkit_result_thumbnail] | https://www.montesi.it/sites/default/files/styles/linkit_result_thumbnail/public/banner/rullatura.jpg?itok=CZ9_Gph_ |

| [node:field_banner:linkit_result_thumbnail:filesize] | 1676 |

| [node:field_banner:linkit_result_thumbnail:height] | 50 |

| [node:field_banner:linkit_result_thumbnail:mimetype] | image/jpeg |

| [node:field_banner:linkit_result_thumbnail:uri] | public://styles/linkit_result_thumbnail/public/banner/rullatura.jpg |

| [node:field_banner:linkit_result_thumbnail:url] | https://www.montesi.it/sites/default/files/styles/linkit_result_thumbnail/public/banner/rullatura.jpg?itok=CZ9_Gph_ |

| [node:field_banner:linkit_result_thumbnail:width] | 50 |

| [node:field_banner:max_325x325] | https://www.montesi.it/sites/default/files/styles/max_325x325/public/banner/rullatura.jpg?itok=3rcHdz31 |

| [node:field_banner:max_325x325:filesize] | 14910 |

| [node:field_banner:max_325x325:height] | 217 |

| [node:field_banner:max_325x325:mimetype] | image/jpeg |

| [node:field_banner:max_325x325:uri] | public://styles/max_325x325/public/banner/rullatura.jpg |

| [node:field_banner:max_325x325:url] | https://www.montesi.it/sites/default/files/styles/max_325x325/public/banner/rullatura.jpg?itok=3rcHdz31 |

| [node:field_banner:max_325x325:width] | 325 |

| [node:field_banner:max_650x650] | https://www.montesi.it/sites/default/files/styles/max_650x650/public/banner/rullatura.jpg?itok=NsxDwUiA |

| [node:field_banner:max_650x650:filesize] | 42662 |

| [node:field_banner:max_650x650:height] | 433 |

| [node:field_banner:max_650x650:mimetype] | image/jpeg |

| [node:field_banner:max_650x650:uri] | public://styles/max_650x650/public/banner/rullatura.jpg |

| [node:field_banner:max_650x650:url] | https://www.montesi.it/sites/default/files/styles/max_650x650/public/banner/rullatura.jpg?itok=NsxDwUiA |

| [node:field_banner:max_650x650:width] | 650 |

| [node:field_banner:max_1300x1300] | https://www.montesi.it/sites/default/files/styles/max_1300x1300/public/banner/rullatura.jpg?itok=982pvY8t |

| [node:field_banner:max_1300x1300:filesize] | 122304 |

| [node:field_banner:max_1300x1300:height] | 866 |

| [node:field_banner:max_1300x1300:mimetype] | image/jpeg |

| [node:field_banner:max_1300x1300:uri] | public://styles/max_1300x1300/public/banner/rullatura.jpg |

| [node:field_banner:max_1300x1300:url] | https://www.montesi.it/sites/default/files/styles/max_1300x1300/public/banner/rullatura.jpg?itok=982pvY8t |

| [node:field_banner:max_1300x1300:width] | 1300 |

| [node:field_banner:max_2600x2600] | https://www.montesi.it/sites/default/files/styles/max_2600x2600/public/banner/rullatura.jpg?itok=m8yD2pPn |

| [node:field_banner:max_2600x2600:filesize] | 208083 |

| [node:field_banner:max_2600x2600:height] | 1333 |

| [node:field_banner:max_2600x2600:mimetype] | image/jpeg |

| [node:field_banner:max_2600x2600:uri] | public://styles/max_2600x2600/public/banner/rullatura.jpg |

| [node:field_banner:max_2600x2600:url] | https://www.montesi.it/sites/default/files/styles/max_2600x2600/public/banner/rullatura.jpg?itok=m8yD2pPn |

| [node:field_banner:max_2600x2600:width] | 2000 |

| [node:field_banner:media_library] | https://www.montesi.it/sites/default/files/styles/media_library/public/banner/rullatura.jpg?itok=YZzkDTJK |

| [node:field_banner:media_library:filesize] | 8427 |

| [node:field_banner:media_library:height] | 147 |

| [node:field_banner:media_library:mimetype] | image/jpeg |

| [node:field_banner:media_library:uri] | public://styles/media_library/public/banner/rullatura.jpg |

| [node:field_banner:media_library:url] | https://www.montesi.it/sites/default/files/styles/media_library/public/banner/rullatura.jpg?itok=YZzkDTJK |

| [node:field_banner:media_library:width] | 220 |

| [node:field_banner:medium] | https://www.montesi.it/sites/default/files/styles/medium/public/banner/rullatura.jpg?itok=4lxzFDbw |

| [node:field_banner:medium:filesize] | 8427 |

| [node:field_banner:medium:height] | 147 |

| [node:field_banner:medium:mimetype] | image/jpeg |

| [node:field_banner:medium:uri] | public://styles/medium/public/banner/rullatura.jpg |

| [node:field_banner:medium:url] | https://www.montesi.it/sites/default/files/styles/medium/public/banner/rullatura.jpg?itok=4lxzFDbw |

| [node:field_banner:medium:width] | 220 |

| [node:field_banner:thumbnail] | https://www.montesi.it/sites/default/files/styles/thumbnail/public/banner/rullatura.jpg?itok=LhHp5esp |

| [node:field_banner:thumbnail:filesize] | 2927 |

| [node:field_banner:thumbnail:height] | 67 |

| [node:field_banner:thumbnail:mimetype] | image/jpeg |

| [node:field_banner:thumbnail:uri] | public://styles/thumbnail/public/banner/rullatura.jpg |

| [node:field_banner:thumbnail:url] | https://www.montesi.it/sites/default/files/styles/thumbnail/public/banner/rullatura.jpg?itok=LhHp5esp |

| [node:field_banner:thumbnail:width] | 100 |

| [node:field_banner:width] | 2000 |

| [node:body] | La tecnologia della filettatura rullata ( processo di deformazione a freddo dell'acciaio ) è stata introdotta dal fondatore Paolo Montesi all'alba degli anni '80, rappresentando all'epoca un processo "particolare e poco conosciuto" seppur sviluppato dall'industria tedesca già nei primi anni del novecento. Le prime rullatrici tedesche rappresentarono un apripista nell'approfondimento dei vantaggi del processo legati alla produttività ed economicità della filettatura rullata. La crescita aziendale è stata accompagnata anche dalla diffusione sul mercato nazionale ed europeo dei prodotti rullati Montesi, tanto da riconoscere il brand associandolo al prodotto. Negli ultimi decenni l'esperienza sulla rullatura si è estesa anche ai processi di formatura per ottenere viti senza fine e splines, attribuendo a Montesi il riconoscimento di azienda di riferimento a livello italiano ed europeo nelle forniture di prodotti rullati di elevata qualità. Ad oggi possiamo vantare collaborazioni con importanti multinazionali europee per forniture e prototipazioni di componenti meccanici sui quali la rullatura assume importanza strategica. |

| [node:field_catalogo] | |

| [node:field_categorie] | |

| [node:comment-count] | 0 |

| [node:comment] | |

| [node:nid] | 28 |

| [node:content-type] | Basic page |

| [node:content-type:description] | Use <em>basic pages</em> for your static content, such as an 'About us' page. |

| [node:content-type:edit-url] | https://www.montesi.it/en/admin/structure/types/manage/page |

| [node:content-type:machine-name] | page |

| [node:content-type:name] | Basic page |

| [node:content-type:node-count] | 1 |

| [node:changed] | Wed, 12/23/2020 - 10:24 |

| [node:changed:fallback] | Wed, 12/23/2020 - 10:24 |

| [node:changed:html_date] | 2020-12-23 |

| [node:changed:html_datetime] | 2020-12-23T10:24:57+0100 |

| [node:changed:html_month] | 2020-12 |

| [node:changed:html_time] | 10:24:57 |

| [node:changed:html_week] | 2020-W52 |

| [node:changed:html_year] | 2020 |

| [node:changed:html_yearless_date] | 12-23 |

| [node:changed:long] | Wednesday, December 23, 2020 - 10:24 |

| [node:changed:medium] | Wed, 12/23/2020 - 10:24 |

| [node:changed:raw] | 1608715497 |

| [node:changed:short] | 12/23/2020 - 10:24 |

| [node:changed:since] | 2 years 2 months |

| [node:created] | Fri, 06/28/2019 - 09:49 |

| [node:created:fallback] | Fri, 06/28/2019 - 09:49 |

| [node:created:html_date] | 2019-06-28 |

| [node:created:html_datetime] | 2019-06-28T09:49:50+0200 |

| [node:created:html_month] | 2019-06 |

| [node:created:html_time] | 09:49:50 |

| [node:created:html_week] | 2019-W26 |

| [node:created:html_year] | 2019 |

| [node:created:html_yearless_date] | 06-28 |

| [node:created:long] | Friday, June 28, 2019 - 09:49 |

| [node:created:medium] | Fri, 06/28/2019 - 09:49 |

| [node:created:raw] | 1561708190 |

| [node:created:short] | 06/28/2019 - 09:49 |

| [node:created:since] | 3 years 8 months |

| [node:edit-url] | https://www.montesi.it/en/node/28/edit |

| [node:field_file_allegato] | |

| [node:field_file_cad_allegato] | |

| [node:field_file_scheda_tecnica] | |

| [node:field_forma_madrevite] | |

| [node:field_fullwidth_text] | Spento |

| [node:field_gamma] | |

| [node:field_highlight] | We have always made chips. |

| [node:field_highlight:value] | <p>We have always made chips.<br /> Then we decided to add other things.</p> |

| [node:field_highlight:format] | basic_html |

| [node:field_image] | |

| [node:langcode] | en |

| [node:field_link_ecommerce] | |

| [node:field_link_file_cad] | |

| [node:field_materiale_madrevite] | |

| [node:field_materiale_vite] | |

| [node:menu-link] | Rolling |

| [node:menu-link:edit-url] | https://www.montesi.it/en/admin/structure/menu/item/27/edit |

| [node:menu-link:menu] | Main navigation |

| [node:menu-link:menu:description] | Site section links |

| [node:menu-link:menu:edit-url] | https://www.montesi.it/en/admin/structure/menu/manage/main |

| [node:menu-link:menu:machine-name] | main |

| [node:menu-link:menu:menu-link-count] | 46 |

| [node:menu-link:menu:name] | Main navigation |

| [node:menu-link:title] | Rolling |

| [node:menu-link:url] | https://www.montesi.it/en/rolling |

| [node:menu-link:url:absolute] | https://www.montesi.it/en/rolling |

| [node:menu-link:url:args] | , rolling |

| [node:menu-link:url:args:count] | 1 |

| [node:menu-link:url:args:first] | rolling |

| [node:menu-link:url:args:join-path] | rolling |

| [node:menu-link:url:args:last] | rolling |

| [node:menu-link:url:args:reversed] | rolling |

| [node:menu-link:url:brief] | www.montesi.it/en/rolling |

| [node:menu-link:url:path] | /rolling |

| [node:menu-link:url:relative] | /en/rolling |

| [node:menu-link:url:unaliased] | https://www.montesi.it/en/node/28 |

| [node:menu-link:url:unaliased:absolute] | https://www.montesi.it/en/node/28 |

| [node:menu-link:url:unaliased:args] | , node, 28 |

| [node:menu-link:url:unaliased:brief] | www.montesi.it/en/node/28 |

| [node:menu-link:url:unaliased:path] | /node/28 |

| [node:menu-link:url:unaliased:relative] | /en/node/28 |

| [node:field_metatags] | |

| [node:comment-count-new] | |

| [node:original] | |

| [node:vid] | 1405 |

| [node:log] | |

| [node:field_sections] | THE ROLLING PROCESS AND ITS ADVANTAGES

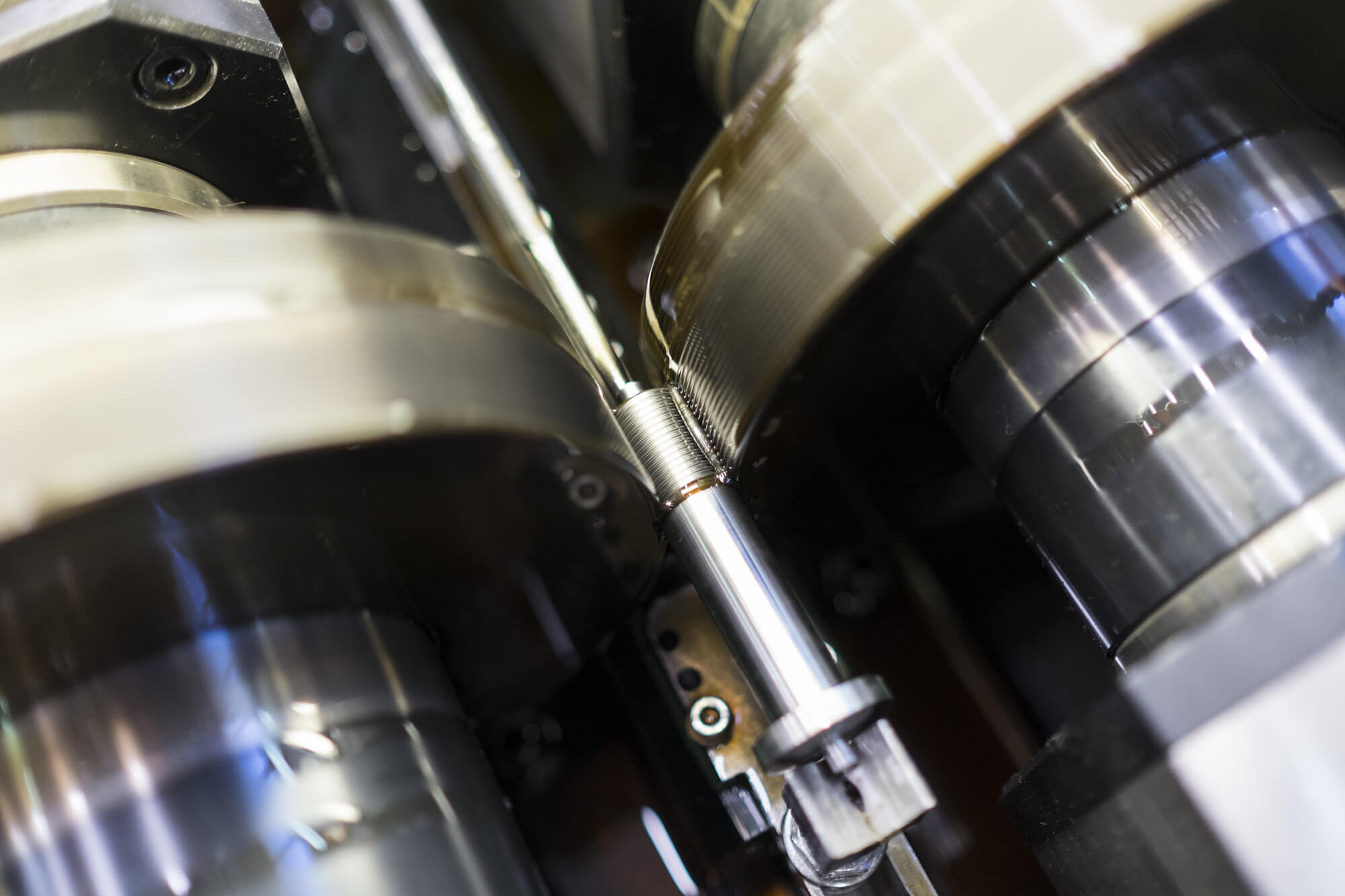

Rolling is a mechanical process without chip removal that provides for the creation of threads, forming, and surface superfinishing by passing the piece between rolling tools in continuous rotation, which deform and refinish the outer surface of the raw material until the desired shape and sizes are reached. Rolling is preferred to turning and grinding since plastic deformation on the piece involves the hardening of the material, increasing its hardness and preserving its mechanical properties. Also, since cracks cannot be detected, the rolled product has a better fatigue strength. This is a process appreciated in fields such as aerospace (e.g., screws without cracks), automotive (splines on the engine shaft), and the railway, oil & gas, wind turbine, and off-road fields (earthmoving and farming machines), also thanks to the reduction in costs of the product. The advantages of the rolling process can be summed up as follows:

APPLICATIONS FOR THREADING

BAR THREADING TO OBTAIN MANOEUVRING SCREWS, MOVEMENT SCREWS, AND BALL RECIRCULATION SCREWS The so-called “in passing” roll threading process typically starts from the processing of steel bars, which are completely threaded. From this, screws in the length desired are obtained, which are processed at the ends for support and motion transmission. Screws threaded by rolling, paired with sliding nuts, constitute a translation system used in a wide range of applications, both for manoeuvring heavy loads (rolled trapezoidal screws) and for moving lighter equipment with the need for greater speed (movement screws). Roll threading also allows the creation of profiles for pairing with ball circulation nuts. Rolled screws for ball circulation nuts are one of the excellent potentials of roll threading, where precision is reached with advanced technology and processes with CNC numeric control. ROLL THREADING OF SEMI-FINISHED PRODUCTS The so called “dive” roll threading starts with the processing of previously turned components. The excellence of the end result is also related to the quality of the preparatory turning phase, a synergy with which we have vast experience and expertise. Roll threading on mechanical components (M, Tr, WhitWorth, UNC, UNF, UNEF threads) is a choice bound for special used (avionics) and ensures excellent resistance and finish. Their synergy with our departments in the REMOVAL division allows a wide range of components with removed threading. APPLICATIONS FOR FORMING

ROLLED WORMS With rolling, plastic shaping of steel can be obtained to create precision worms, which are typically paired with crown gears in angular motion transmission or reduction applications. These are processes where the movement of the material is very high and therefore, millesimal control of the large compression power involved is fundamental. The most suitable generation of rolling machines is the numerically controlled one, which can manage the PSF (precision screw forming) process. Rolling on tailstocks is the most advanced technical solution to create worms with an appreciable degree of precision, even in applications where worms obtained by notch forming are usually used. ROLLED SPLINES (PARALLEL SPLINING) Forced seating is a type of shaft-hub connection. The shaft spline can be obtained by rolling using a rack or rollers. Rack splining offers process stability and high productivity. Splining with rollers offers size flexibility and extreme precision on the involutes. APPLICATIONS FOR SURFACE SUPERFINISHING

Rolled superfinishing, also known as lapping, may be considered to be an excellent solution for obtaining surface finishes on cylindrical parts with low roughness. The roughness values that can be obtained with this process are better than grinding and can be performed in a highly efficient and economical manner. The synergy and continuous feedback between turning and the subsequent rolled superfinishing are indispensable for obtaining excellent results. Shafts, rods, and drive screws in the valve sector are just a few of the typical applications of this process. THE MONTESI ADVANTAGES IN PRODUCTS WITH ROLL THREADING

SCREWS

NUTS

MADE-TO-ORDER AND SPECIAL PRODUCTS

EQUIPMENTRolling machines:

Rack forming rolling machine:

Rolling tools:

ROLL THREADING TECHNOLOGYTrapezoidal profile manoeuvring screw threading Drive/multi-start screw threading Recirculation screw threading Automated straightening Text

WHY CHOOSE MONTESI

|

| [node:field_sections:0] | THE ROLLING PROCESS AND ITS ADVANTAGES

Rolling is a mechanical process without chip removal that provides for the creation of threads, forming, and surface superfinishing by passing the piece between rolling tools in continuous rotation, which deform and refinish the outer surface of the raw material until the desired shape and sizes are reached. Rolling is preferred to turning and grinding since plastic deformation on the piece involves the hardening of the material, increasing its hardness and preserving its mechanical properties. Also, since cracks cannot be detected, the rolled product has a better fatigue strength. This is a process appreciated in fields such as aerospace (e.g., screws without cracks), automotive (splines on the engine shaft), and the railway, oil & gas, wind turbine, and off-road fields (earthmoving and farming machines), also thanks to the reduction in costs of the product. The advantages of the rolling process can be summed up as follows:

APPLICATIONS FOR THREADING

BAR THREADING TO OBTAIN MANOEUVRING SCREWS, MOVEMENT SCREWS, AND BALL RECIRCULATION SCREWS The so-called “in passing” roll threading process typically starts from the processing of steel bars, which are completely threaded. From this, screws in the length desired are obtained, which are processed at the ends for support and motion transmission. Screws threaded by rolling, paired with sliding nuts, constitute a translation system used in a wide range of applications, both for manoeuvring heavy loads (rolled trapezoidal screws) and for moving lighter equipment with the need for greater speed (movement screws). Roll threading also allows the creation of profiles for pairing with ball circulation nuts. Rolled screws for ball circulation nuts are one of the excellent potentials of roll threading, where precision is reached with advanced technology and processes with CNC numeric control. ROLL THREADING OF SEMI-FINISHED PRODUCTS The so called “dive” roll threading starts with the processing of previously turned components. The excellence of the end result is also related to the quality of the preparatory turning phase, a synergy with which we have vast experience and expertise. Roll threading on mechanical components (M, Tr, WhitWorth, UNC, UNF, UNEF threads) is a choice bound for special used (avionics) and ensures excellent resistance and finish. Their synergy with our departments in the REMOVAL division allows a wide range of components with removed threading. APPLICATIONS FOR FORMING

ROLLED WORMS With rolling, plastic shaping of steel can be obtained to create precision worms, which are typically paired with crown gears in angular motion transmission or reduction applications. These are processes where the movement of the material is very high and therefore, millesimal control of the large compression power involved is fundamental. The most suitable generation of rolling machines is the numerically controlled one, which can manage the PSF (precision screw forming) process. Rolling on tailstocks is the most advanced technical solution to create worms with an appreciable degree of precision, even in applications where worms obtained by notch forming are usually used. ROLLED SPLINES (PARALLEL SPLINING) Forced seating is a type of shaft-hub connection. The shaft spline can be obtained by rolling using a rack or rollers. Rack splining offers process stability and high productivity. Splining with rollers offers size flexibility and extreme precision on the involutes. APPLICATIONS FOR SURFACE SUPERFINISHING

Rolled superfinishing, also known as lapping, may be considered to be an excellent solution for obtaining surface finishes on cylindrical parts with low roughness. The roughness values that can be obtained with this process are better than grinding and can be performed in a highly efficient and economical manner. The synergy and continuous feedback between turning and the subsequent rolled superfinishing are indispensable for obtaining excellent results. Shafts, rods, and drive screws in the valve sector are just a few of the typical applications of this process. THE MONTESI ADVANTAGES IN PRODUCTS WITH ROLL THREADING

SCREWS

NUTS

MADE-TO-ORDER AND SPECIAL PRODUCTS

|

| [node:field_sections:0:entity] | Rolling > Sections |

| [node:field_sections:0:entity:field_accordion] | THE ROLLING PROCESS AND ITS ADVANTAGES

Rolling is a mechanical process without chip removal that provides for the creation of threads, forming, and surface superfinishing by passing the piece between rolling tools in continuous rotation, which deform and refinish the outer surface of the raw material until the desired shape and sizes are reached. Rolling is preferred to turning and grinding since plastic deformation on the piece involves the hardening of the material, increasing its hardness and preserving its mechanical properties. Also, since cracks cannot be detected, the rolled product has a better fatigue strength. This is a process appreciated in fields such as aerospace (e.g., screws without cracks), automotive (splines on the engine shaft), and the railway, oil & gas, wind turbine, and off-road fields (earthmoving and farming machines), also thanks to the reduction in costs of the product. The advantages of the rolling process can be summed up as follows:

APPLICATIONS FOR THREADING

BAR THREADING TO OBTAIN MANOEUVRING SCREWS, MOVEMENT SCREWS, AND BALL RECIRCULATION SCREWS The so-called “in passing” roll threading process typically starts from the processing of steel bars, which are completely threaded. From this, screws in the length desired are obtained, which are processed at the ends for support and motion transmission. Screws threaded by rolling, paired with sliding nuts, constitute a translation system used in a wide range of applications, both for manoeuvring heavy loads (rolled trapezoidal screws) and for moving lighter equipment with the need for greater speed (movement screws). Roll threading also allows the creation of profiles for pairing with ball circulation nuts. Rolled screws for ball circulation nuts are one of the excellent potentials of roll threading, where precision is reached with advanced technology and processes with CNC numeric control. ROLL THREADING OF SEMI-FINISHED PRODUCTS The so called “dive” roll threading starts with the processing of previously turned components. The excellence of the end result is also related to the quality of the preparatory turning phase, a synergy with which we have vast experience and expertise. Roll threading on mechanical components (M, Tr, WhitWorth, UNC, UNF, UNEF threads) is a choice bound for special used (avionics) and ensures excellent resistance and finish. Their synergy with our departments in the REMOVAL division allows a wide range of components with removed threading. APPLICATIONS FOR FORMING

ROLLED WORMS With rolling, plastic shaping of steel can be obtained to create precision worms, which are typically paired with crown gears in angular motion transmission or reduction applications. These are processes where the movement of the material is very high and therefore, millesimal control of the large compression power involved is fundamental. The most suitable generation of rolling machines is the numerically controlled one, which can manage the PSF (precision screw forming) process. Rolling on tailstocks is the most advanced technical solution to create worms with an appreciable degree of precision, even in applications where worms obtained by notch forming are usually used. ROLLED SPLINES (PARALLEL SPLINING) Forced seating is a type of shaft-hub connection. The shaft spline can be obtained by rolling using a rack or rollers. Rack splining offers process stability and high productivity. Splining with rollers offers size flexibility and extreme precision on the involutes. APPLICATIONS FOR SURFACE SUPERFINISHING

Rolled superfinishing, also known as lapping, may be considered to be an excellent solution for obtaining surface finishes on cylindrical parts with low roughness. The roughness values that can be obtained with this process are better than grinding and can be performed in a highly efficient and economical manner. The synergy and continuous feedback between turning and the subsequent rolled superfinishing are indispensable for obtaining excellent results. Shafts, rods, and drive screws in the valve sector are just a few of the typical applications of this process. THE MONTESI ADVANTAGES IN PRODUCTS WITH ROLL THREADING

SCREWS

NUTS

MADE-TO-ORDER AND SPECIAL PRODUCTS

|

| [node:field_sections:0:entity:behavior_settings] | a:0:{} |

| [node:field_sections:0:entity:created] | Tue, 07/02/2019 - 11:36 |

| [node:field_sections:0:entity:revision_default] | On |

| [node:field_sections:0:entity:default_langcode] | On |

| [node:field_sections:0:entity:id] | 531 |

| [node:field_sections:0:entity:langcode] | English |

| [node:field_sections:0:entity:type] | Accordion container |

| [node:field_sections:0:entity:parent_field_name] | field_sections |

| [node:field_sections:0:entity:parent_id] | 28 |

| [node:field_sections:0:entity:parent_type] | node |

| [node:field_sections:0:entity:status] | Acceso |

| [node:field_sections:0:entity:revision_id] | 5092 |

| [node:field_sections:0:entity:revision_translation_affected] | On |

| [node:field_sections:0:entity:content_translation_outdated] | Off |

| [node:field_sections:0:entity:content_translation_source] | Not specified |

| [node:field_sections:0:entity:uuid] | fe6cf245-176a-43cf-84b9-fddc6fc45eba |

| [node:field_sections:0:target_id] | 531 |

| [node:field_sections:0:target_revision_id] | 5092 |

| [node:field_sections:1] | EQUIPMENTRolling machines:

Rack forming rolling machine:

Rolling tools:

|

| [node:field_sections:1:entity] | Rolling > Sections |

| [node:field_sections:1:entity:field_image] |

|

| [node:field_sections:1:entity:behavior_settings] | a:0:{} |

| [node:field_sections:1:entity:created] | Tue, 07/02/2019 - 11:35 |

| [node:field_sections:1:entity:revision_default] | On |

| [node:field_sections:1:entity:default_langcode] | On |

| [node:field_sections:1:entity:id] | 532 |

| [node:field_sections:1:entity:field_image_dx] | Spento |

| [node:field_sections:1:entity:langcode] | English |

| [node:field_sections:1:entity:type] | Testo ed immagine a lato |

| [node:field_sections:1:entity:parent_field_name] | field_sections |

| [node:field_sections:1:entity:parent_id] | 28 |

| [node:field_sections:1:entity:parent_type] | node |

| [node:field_sections:1:entity:status] | Acceso |

| [node:field_sections:1:entity:revision_id] | 4979 |

| [node:field_sections:1:entity:field_sfondo_verde] | Spento |

| [node:field_sections:1:entity:field_testo] | EQUIPMENTRolling machines:

Rack forming rolling machine:

Rolling tools:

|

| [node:field_sections:1:entity:content_translation_outdated] | Off |

| [node:field_sections:1:entity:content_translation_source] | Not specified |

| [node:field_sections:1:entity:uuid] | 088f3f60-97d1-42de-83e3-49fea81d21c5 |

| [node:field_sections:1:target_id] | 532 |

| [node:field_sections:1:target_revision_id] | 4979 |

| [node:field_sections:2] | ROLL THREADING TECHNOLOGYTrapezoidal profile manoeuvring screw threading Drive/multi-start screw threading Recirculation screw threading Automated straightening |

| [node:field_sections:2:entity] | Rolling > Sections |

| [node:field_sections:2:entity:field_image] |

|

| [node:field_sections:2:entity:behavior_settings] | a:0:{} |

| [node:field_sections:2:entity:created] | Tue, 07/02/2019 - 11:36 |

| [node:field_sections:2:entity:revision_default] | On |

| [node:field_sections:2:entity:default_langcode] | On |

| [node:field_sections:2:entity:id] | 533 |

| [node:field_sections:2:entity:field_image_dx] | Acceso |

| [node:field_sections:2:entity:langcode] | English |

| [node:field_sections:2:entity:type] | Testo ed immagine a lato |

| [node:field_sections:2:entity:parent_field_name] | field_sections |

| [node:field_sections:2:entity:parent_id] | 28 |

| [node:field_sections:2:entity:parent_type] | node |

| [node:field_sections:2:entity:status] | Acceso |

| [node:field_sections:2:entity:revision_id] | 4980 |

| [node:field_sections:2:entity:field_sfondo_verde] | Acceso |

| [node:field_sections:2:entity:field_testo] | ROLL THREADING TECHNOLOGYTrapezoidal profile manoeuvring screw threading Drive/multi-start screw threading Recirculation screw threading Automated straightening |

| [node:field_sections:2:entity:content_translation_outdated] | Off |

| [node:field_sections:2:entity:content_translation_source] | Not specified |

| [node:field_sections:2:entity:uuid] | 33a25709-b4e8-49ac-afda-a49ec6833480 |

| [node:field_sections:2:target_id] | 533 |

| [node:field_sections:2:target_revision_id] | 4980 |

| [node:summary] | <p>La tecnologia della filettatura rullata ( processo di deformazione a freddo dell'acciaio ) è stata introdotta dal fondatore Paolo Montesi all'alba degli anni '80, rappresentando all'epoca un processo "particolare e poco conosciuto" seppur sviluppato dall'industria tedesca già nei primi anni del novecento.</p> <p>Le prime rullatrici tedesche rappresentarono un apripista nell'approfondimento dei vantaggi del processo legati alla produttività ed economicità della filettatura rullata.</p> |

| [node:field_tags] | |

| [node:field_read_more_text] | |

| [node:field_tipologia] | |

| [node:title] | Rolling |

| [node:source] | |

| [node:source:author] | david |

| [node:source:author:account-name] | david |

| [node:source:author:created] | Thu, 06/27/2019 - 16:47 |

| [node:source:author:created:fallback] | Thu, 06/27/2019 - 16:47 |

| [node:source:author:created:html_date] | 2019-06-27 |

| [node:source:author:created:html_datetime] | 2019-06-27T16:47:42+0200 |

| [node:source:author:created:html_month] | 2019-06 |

| [node:source:author:created:html_time] | 16:47:42 |

| [node:source:author:created:html_week] | 2019-W26 |

| [node:source:author:created:html_year] | 2019 |

| [node:source:author:created:html_yearless_date] | 06-27 |

| [node:source:author:created:long] | Thursday, June 27, 2019 - 16:47 |

| [node:source:author:created:medium] | Thu, 06/27/2019 - 16:47 |

| [node:source:author:created:raw] | 1561646862 |

| [node:source:author:created:short] | 06/27/2019 - 16:47 |

| [node:source:author:created:since] | 3 years 8 months |

| [node:source:author:name] | david |

| [node:source:author:display-name] | david |

| [node:source:author:edit-url] | https://www.montesi.it/it/user/15/edit |

| [node:source:author:mail] | david@weevo.it |

| [node:source:author:last-login] | Fri, 11/25/2022 - 08:17 |

| [node:source:author:last-login:fallback] | Fri, 11/25/2022 - 08:17 |

| [node:source:author:last-login:html_date] | 2022-11-25 |

| [node:source:author:last-login:html_datetime] | 2022-11-25T08:17:23+0100 |

| [node:source:author:last-login:html_month] | 2022-11 |

| [node:source:author:last-login:html_time] | 08:17:23 |

| [node:source:author:last-login:html_week] | 2022-W47 |

| [node:source:author:last-login:html_year] | 2022 |

| [node:source:author:last-login:html_yearless_date] | 11-25 |

| [node:source:author:last-login:long] | Friday, November 25, 2022 - 08:17 |

| [node:source:author:last-login:medium] | Fri, 11/25/2022 - 08:17 |

| [node:source:author:last-login:raw] | 1669360643 |

| [node:source:author:last-login:short] | 11/25/2022 - 08:17 |

| [node:source:author:last-login:since] | 3 months 2 weeks |

| [node:source:author:roles] | authenticated, administrator |

| [node:source:author:roles:count] | 2 |

| [node:source:author:roles:first] | authenticated |

| [node:source:author:roles:join-path] | authenticated/administrator |

| [node:source:author:roles:keys] | authenticated, administrator |

| [node:source:author:roles:last] | administrator |

| [node:source:author:roles:reversed] | administrator, authenticated |

| [node:source:author:url] | https://www.montesi.it/it/user/15 |

| [node:source:author:url:absolute] | https://www.montesi.it/it/user/15 |

| [node:source:author:url:args] | , user, 15 |

| [node:source:author:url:brief] | www.montesi.it/it/user/15 |

| [node:source:author:url:path] | /user/15 |

| [node:source:author:url:relative] | /it/user/15 |

| [node:source:author:url:unaliased] | https://www.montesi.it/it/user/15 |

| [node:source:author:uid] | 15 |

| [node:source:author:role-ids] | 0,1 |

| [node:source:author:role-names] | authenticated,administrator |

| [node:source:field_banner] |

|

| [node:source:field_banner:crop_200x200] | https://www.montesi.it/sites/default/files/styles/crop_200x200/public/banner/rullatura.jpg?itok=LJ7C4S79 |

| [node:source:field_banner:crop_200x200:filesize] | 7203 |

| [node:source:field_banner:crop_200x200:height] | 133 |

| [node:source:field_banner:crop_200x200:mimetype] | image/jpeg |

| [node:source:field_banner:crop_200x200:uri] | public://styles/crop_200x200/public/banner/rullatura.jpg |

| [node:source:field_banner:crop_200x200:url] | https://www.montesi.it/sites/default/files/styles/crop_200x200/public/banner/rullatura.jpg?itok=LJ7C4S79 |

| [node:source:field_banner:crop_200x200:width] | 200 |

| [node:source:field_banner:crop_470x270] | https://www.montesi.it/sites/default/files/styles/crop_470x270/public/banner/rullatura.jpg?itok=UlB-qZDa |

| [node:source:field_banner:crop_470x270:filesize] | 26025 |

| [node:source:field_banner:crop_470x270:height] | 313 |

| [node:source:field_banner:crop_470x270:mimetype] | image/jpeg |

| [node:source:field_banner:crop_470x270:uri] | public://styles/crop_470x270/public/banner/rullatura.jpg |

| [node:source:field_banner:crop_470x270:url] | https://www.montesi.it/sites/default/files/styles/crop_470x270/public/banner/rullatura.jpg?itok=UlB-qZDa |

| [node:source:field_banner:crop_470x270:width] | 470 |

| [node:source:field_banner:crop_570x380] | https://www.montesi.it/sites/default/files/styles/crop_570x380/public/banner/rullatura.jpg?itok=pvKAJ9di |

| [node:source:field_banner:crop_570x380:filesize] | 34852 |

| [node:source:field_banner:crop_570x380:height] | 380 |

| [node:source:field_banner:crop_570x380:mimetype] | image/jpeg |

| [node:source:field_banner:crop_570x380:uri] | public://styles/crop_570x380/public/banner/rullatura.jpg |

| [node:source:field_banner:crop_570x380:url] | https://www.montesi.it/sites/default/files/styles/crop_570x380/public/banner/rullatura.jpg?itok=pvKAJ9di |

| [node:source:field_banner:crop_570x380:width] | 570 |

| [node:source:field_banner:crop_1200x500] | https://www.montesi.it/sites/default/files/styles/crop_1200x500/public/banner/rullatura.jpg?h=1c5b1964&itok=yJnfMnk6 |

| [node:source:field_banner:crop_1200x500:filesize] | 78988 |

| [node:source:field_banner:crop_1200x500:height] | 500 |

| [node:source:field_banner:crop_1200x500:mimetype] | image/jpeg |

| [node:source:field_banner:crop_1200x500:uri] | public://styles/crop_1200x500/public/banner/rullatura.jpg |

| [node:source:field_banner:crop_1200x500:url] | https://www.montesi.it/sites/default/files/styles/crop_1200x500/public/banner/rullatura.jpg?h=1c5b1964&itok=yJnfMnk6 |

| [node:source:field_banner:crop_1200x500:width] | 1200 |

| [node:source:field_banner:crop] | https://www.montesi.it/sites/default/files/styles/crop/public/banner/rullatura.jpg?h=629a1ba2&itok=TiDlspg9 |

| [node:source:field_banner:crop:filesize] | 79770 |

| [node:source:field_banner:crop:height] | 400 |

| [node:source:field_banner:crop:mimetype] | image/jpeg |

| [node:source:field_banner:crop:uri] | public://styles/crop/public/banner/rullatura.jpg |

| [node:source:field_banner:crop:url] | https://www.montesi.it/sites/default/files/styles/crop/public/banner/rullatura.jpg?h=629a1ba2&itok=TiDlspg9 |

| [node:source:field_banner:crop:width] | 1400 |

| [node:source:field_banner:entity] | rullatura.jpg |

| [node:source:field_banner:entity:basename] | rullatura.jpg |

| [node:source:field_banner:entity:changed] | Ven, 02/14/2020 - 18:55 |

| [node:source:field_banner:entity:created] | Ven, 02/14/2020 - 18:55 |

| [node:source:field_banner:entity:extension] | jpg |

| [node:source:field_banner:entity:size-raw] | 211645 |

| [node:source:field_banner:entity:fid] | 376 |

| [node:source:field_banner:entity:name] | rullatura.jpg |

| [node:source:field_banner:entity:size] | 206.68 KB |

| [node:source:field_banner:entity:mime] | image/jpeg |

| [node:source:field_banner:entity:owner] | david |

| [node:source:field_banner:entity:path] | public://banner/rullatura.jpg |

| [node:source:field_banner:entity:url] | https://www.montesi.it/sites/default/files/banner/rullatura.jpg |

| [node:source:field_banner:target_id] | 376 |

| [node:source:field_banner:height] | 1333 |

| [node:source:field_banner:large] | https://www.montesi.it/sites/default/files/styles/large/public/banner/rullatura.jpg?itok=0xaUqNbb |

| [node:source:field_banner:large:filesize] | 26598 |

| [node:source:field_banner:large:height] | 320 |

| [node:source:field_banner:large:mimetype] | image/jpeg |

| [node:source:field_banner:large:uri] | public://styles/large/public/banner/rullatura.jpg |

| [node:source:field_banner:large:url] | https://www.montesi.it/sites/default/files/styles/large/public/banner/rullatura.jpg?itok=0xaUqNbb |

| [node:source:field_banner:large:width] | 480 |

| [node:source:field_banner:linkit_result_thumbnail] | https://www.montesi.it/sites/default/files/styles/linkit_result_thumbnail/public/banner/rullatura.jpg?itok=CZ9_Gph_ |

| [node:source:field_banner:linkit_result_thumbnail:filesize] | 1676 |

| [node:source:field_banner:linkit_result_thumbnail:height] | 50 |

| [node:source:field_banner:linkit_result_thumbnail:mimetype] | image/jpeg |

| [node:source:field_banner:linkit_result_thumbnail:uri] | public://styles/linkit_result_thumbnail/public/banner/rullatura.jpg |

| [node:source:field_banner:linkit_result_thumbnail:url] | https://www.montesi.it/sites/default/files/styles/linkit_result_thumbnail/public/banner/rullatura.jpg?itok=CZ9_Gph_ |

| [node:source:field_banner:linkit_result_thumbnail:width] | 50 |

| [node:source:field_banner:max_325x325] | https://www.montesi.it/sites/default/files/styles/max_325x325/public/banner/rullatura.jpg?itok=3rcHdz31 |

| [node:source:field_banner:max_325x325:filesize] | 14910 |

| [node:source:field_banner:max_325x325:height] | 217 |

| [node:source:field_banner:max_325x325:mimetype] | image/jpeg |

| [node:source:field_banner:max_325x325:uri] | public://styles/max_325x325/public/banner/rullatura.jpg |

| [node:source:field_banner:max_325x325:url] | https://www.montesi.it/sites/default/files/styles/max_325x325/public/banner/rullatura.jpg?itok=3rcHdz31 |

| [node:source:field_banner:max_325x325:width] | 325 |

| [node:source:field_banner:max_650x650] | https://www.montesi.it/sites/default/files/styles/max_650x650/public/banner/rullatura.jpg?itok=NsxDwUiA |

| [node:source:field_banner:max_650x650:filesize] | 42662 |

| [node:source:field_banner:max_650x650:height] | 433 |

| [node:source:field_banner:max_650x650:mimetype] | image/jpeg |

| [node:source:field_banner:max_650x650:uri] | public://styles/max_650x650/public/banner/rullatura.jpg |

| [node:source:field_banner:max_650x650:url] | https://www.montesi.it/sites/default/files/styles/max_650x650/public/banner/rullatura.jpg?itok=NsxDwUiA |

| [node:source:field_banner:max_650x650:width] | 650 |

| [node:source:field_banner:max_1300x1300] | https://www.montesi.it/sites/default/files/styles/max_1300x1300/public/banner/rullatura.jpg?itok=982pvY8t |

| [node:source:field_banner:max_1300x1300:filesize] | 122304 |

| [node:source:field_banner:max_1300x1300:height] | 866 |

| [node:source:field_banner:max_1300x1300:mimetype] | image/jpeg |

| [node:source:field_banner:max_1300x1300:uri] | public://styles/max_1300x1300/public/banner/rullatura.jpg |

| [node:source:field_banner:max_1300x1300:url] | https://www.montesi.it/sites/default/files/styles/max_1300x1300/public/banner/rullatura.jpg?itok=982pvY8t |

| [node:source:field_banner:max_1300x1300:width] | 1300 |

| [node:source:field_banner:max_2600x2600] | https://www.montesi.it/sites/default/files/styles/max_2600x2600/public/banner/rullatura.jpg?itok=m8yD2pPn |

| [node:source:field_banner:max_2600x2600:filesize] | 208083 |

| [node:source:field_banner:max_2600x2600:height] | 1333 |

| [node:source:field_banner:max_2600x2600:mimetype] | image/jpeg |

| [node:source:field_banner:max_2600x2600:uri] | public://styles/max_2600x2600/public/banner/rullatura.jpg |

| [node:source:field_banner:max_2600x2600:url] | https://www.montesi.it/sites/default/files/styles/max_2600x2600/public/banner/rullatura.jpg?itok=m8yD2pPn |

| [node:source:field_banner:max_2600x2600:width] | 2000 |

| [node:source:field_banner:media_library] | https://www.montesi.it/sites/default/files/styles/media_library/public/banner/rullatura.jpg?itok=YZzkDTJK |

| [node:source:field_banner:media_library:filesize] | 8427 |

| [node:source:field_banner:media_library:height] | 147 |

| [node:source:field_banner:media_library:mimetype] | image/jpeg |

| [node:source:field_banner:media_library:uri] | public://styles/media_library/public/banner/rullatura.jpg |

| [node:source:field_banner:media_library:url] | https://www.montesi.it/sites/default/files/styles/media_library/public/banner/rullatura.jpg?itok=YZzkDTJK |

| [node:source:field_banner:media_library:width] | 220 |

| [node:source:field_banner:medium] | https://www.montesi.it/sites/default/files/styles/medium/public/banner/rullatura.jpg?itok=4lxzFDbw |

| [node:source:field_banner:medium:filesize] | 8427 |

| [node:source:field_banner:medium:height] | 147 |

| [node:source:field_banner:medium:mimetype] | image/jpeg |

| [node:source:field_banner:medium:uri] | public://styles/medium/public/banner/rullatura.jpg |

| [node:source:field_banner:medium:url] | https://www.montesi.it/sites/default/files/styles/medium/public/banner/rullatura.jpg?itok=4lxzFDbw |

| [node:source:field_banner:medium:width] | 220 |

| [node:source:field_banner:thumbnail] | https://www.montesi.it/sites/default/files/styles/thumbnail/public/banner/rullatura.jpg?itok=LhHp5esp |

| [node:source:field_banner:thumbnail:filesize] | 2927 |

| [node:source:field_banner:thumbnail:height] | 67 |

| [node:source:field_banner:thumbnail:mimetype] | image/jpeg |

| [node:source:field_banner:thumbnail:uri] | public://styles/thumbnail/public/banner/rullatura.jpg |

| [node:source:field_banner:thumbnail:url] | https://www.montesi.it/sites/default/files/styles/thumbnail/public/banner/rullatura.jpg?itok=LhHp5esp |

| [node:source:field_banner:thumbnail:width] | 100 |

| [node:source:field_banner:width] | 2000 |

| [node:source:body] | La tecnologia della filettatura rullata ( processo di deformazione a freddo dell'acciaio ) è stata introdotta dal fondatore Paolo Montesi all'alba degli anni '80, rappresentando all'epoca un processo "particolare e poco conosciuto" seppur sviluppato dall'industria tedesca già nei primi anni del novecento. Le prime rullatrici tedesche rappresentarono un apripista nell'approfondimento dei vantaggi del processo legati alla produttività ed economicità della filettatura rullata. La crescita aziendale è stata accompagnata anche dalla diffusione sul mercato nazionale ed europeo dei prodotti rullati Montesi, tanto da riconoscere il brand associandolo al prodotto. Negli ultimi decenni l'esperienza sulla rullatura si è estesa anche ai processi di formatura per ottenere viti senza fine e splines, attribuendo a Montesi il riconoscimento di azienda di riferimento a livello italiano ed europeo nelle forniture di prodotti rullati di elevata qualità. Ad oggi possiamo vantare collaborazioni con importanti multinazionali europee per forniture e prototipazioni di componenti meccanici sui quali la rullatura assume importanza strategica. |

| [node:source:nid] | 28 |

| [node:source:content-type] | Basic page |

| [node:source:content-type:description] | Use <em>basic pages</em> for your static content, such as an 'About us' page. |

| [node:source:content-type:edit-url] | https://www.montesi.it/en/admin/structure/types/manage/page |

| [node:source:content-type:machine-name] | page |

| [node:source:content-type:name] | Basic page |

| [node:source:content-type:node-count] | 1 |

| [node:source:changed] | Wed, 12/23/2020 - 10:24 |

| [node:source:changed:fallback] | Wed, 12/23/2020 - 10:24 |

| [node:source:changed:html_date] | 2020-12-23 |

| [node:source:changed:html_datetime] | 2020-12-23T10:24:57+0100 |

| [node:source:changed:html_month] | 2020-12 |

| [node:source:changed:html_time] | 10:24:57 |

| [node:source:changed:html_week] | 2020-W52 |

| [node:source:changed:html_year] | 2020 |

| [node:source:changed:html_yearless_date] | 12-23 |

| [node:source:changed:long] | Wednesday, December 23, 2020 - 10:24 |

| [node:source:changed:medium] | Wed, 12/23/2020 - 10:24 |

| [node:source:changed:raw] | 1608715497 |

| [node:source:changed:short] | 12/23/2020 - 10:24 |

| [node:source:changed:since] | 2 years 2 months |

| [node:source:created] | Fri, 06/28/2019 - 09:49 |

| [node:source:created:fallback] | Fri, 06/28/2019 - 09:49 |

| [node:source:created:html_date] | 2019-06-28 |

| [node:source:created:html_datetime] | 2019-06-28T09:49:50+0200 |

| [node:source:created:html_month] | 2019-06 |

| [node:source:created:html_time] | 09:49:50 |

| [node:source:created:html_week] | 2019-W26 |

| [node:source:created:html_year] | 2019 |

| [node:source:created:html_yearless_date] | 06-28 |

| [node:source:created:long] | Friday, June 28, 2019 - 09:49 |

| [node:source:created:medium] | Fri, 06/28/2019 - 09:49 |

| [node:source:created:raw] | 1561708190 |

| [node:source:created:short] | 06/28/2019 - 09:49 |

| [node:source:created:since] | 3 years 8 months |

| [node:source:edit-url] | https://www.montesi.it/it/node/28/edit |

| [node:source:field_fullwidth_text] | Spento |

| [node:source:field_highlight] | Il truciolo lo facciamo da sempre. |

| [node:source:field_highlight:value] | <p>Il truciolo lo facciamo da sempre.<br /> Poi abbiamo deciso di fare anche altro.</p> |

| [node:source:field_highlight:format] | basic_html |

| [node:source:langcode] | it |

| [node:source:menu-link] | Rolling |

| [node:source:menu-link:edit-url] | https://www.montesi.it/en/admin/structure/menu/item/27/edit |

| [node:source:menu-link:menu] | Main navigation |

| [node:source:menu-link:menu:description] | Site section links |

| [node:source:menu-link:menu:edit-url] | https://www.montesi.it/en/admin/structure/menu/manage/main |

| [node:source:menu-link:menu:machine-name] | main |

| [node:source:menu-link:menu:menu-link-count] | 46 |

| [node:source:menu-link:menu:name] | Main navigation |

| [node:source:menu-link:title] | Rolling |

| [node:source:menu-link:url] | https://www.montesi.it/en/rolling |

| [node:source:menu-link:url:absolute] | https://www.montesi.it/en/rolling |

| [node:source:menu-link:url:args] | , rolling |

| [node:source:menu-link:url:brief] | www.montesi.it/en/rolling |

| [node:source:menu-link:url:path] | /rolling |

| [node:source:menu-link:url:relative] | /en/rolling |

| [node:source:menu-link:url:unaliased] | https://www.montesi.it/en/node/28 |

| [node:source:field_metatags:value] | a:2:{s:5:"title";s:60:"Rullatura meccanica di filetti, viti e splines | [site:name]";s:11:"description";s:155:"La Torneria Montesi è leader tecnologico su scala nazionale nelle lavorazioni di deformazione a freddo mediante rullatura. Scopri di più sul nostro sito!";} |

| [node:source:vid] | 1405 |

| [node:source:field_sections] | Il processo di rullatura e i suoi vantaggi

La rullatura è un processo di lavorazione meccanica senza asportazione di truciolo che prevede la realizzazione di filetti, formature e superfiniture superficiali attraverso il passaggio del pezzo tra utensili rullatori in rotazione continua, i quali deformano e rifiniscono la superficie esterna della materia prima fino al raggiungimento delle geometrie e dimensioni volute. La rullatura viene preferita alla tornitura ed alla molatura in quanto la deformazione plastica cui è sottoposto il pezzo comporta l’incrudimento del materiale, aumentandone la durezza e la conservazione delle sue proprietà meccaniche; inoltre, non essendo rilevabile la presenza di cricche, il prodotto rullato presenta una migliore resistenza alla fatica. Si tratta di lavorazione apprezzata in ambito aerospace (ad es. viti prive di cricche), automotive (spline su albero motore) così come nei settori del ferroviario , oil & gas, eolico e offroad (macchine per il movimento terra e agricole), anche grazie alla riduzione dei costi del prodotto. I vantaggi del processo di rullatura possono essere così riepilogati:

Le applicazioni per la filettatura

FILETTATURA DI BARRE PER OTTENIMENTO DI VITI DI MANOVRA, MOVIMENTAZIONE, VITI A RICIRCOLO DI SFERE Il processo di filettatura rullata cosiddetta "in passata" parte tipicamente dalla lavorazione di barre di acciaio le quali vengono interamente filettate. Da queste si ottengono viti delle lunghezza desiderata e lavorate nei terminali per il supporto e la trasmissione del moto. Le viti filettate con rullatura, accoppiate con madreviti a strisciamento, costituiscono un sistema di traslazione impiegato in un vasto ambito di applicazioni, sia per la manovra di carichi pesanti (viti rullate trapezoidali), sia per la movimentazione di apparati più leggeri con esigenza di maggiore velocità (viti di movimentazione). La filettatura rullata permette anche di ottenere profili per l'accoppiamento con madreviti a ricircolo di sfere. Le viti rullate per madreviti a ricircolo di sfere rappresentano una delle eccellenze delle potenzialità della filettatura rullata, laddove la precisione è raggiunta con tecnologie e processi avanzati a controllo numerico CNC. FILETTATURE RULLATE DI SEMILAVORATI Il processo di filettatura rullata cosiddetta "a tuffo" parte dalla lavorazione di componenti precedentemente torniti. L'eccellenza del risultato finale è funzione anche della qualità della fase preparatoria di tornitura, sinergia nella quale vantiamo vasto know how ed esperienza. La filettatura rullata su componenti meccanici (filetti M, Tr, WhitWorth, UNC, UNF, UNEF,) rappresenta una scelta vincolata per destinazioni speciali ( avionica) e comunque garantisce eccellenti caratteristiche di resistenza e finitura. La sinergia con i nostri reparti della divisione ASPORTAZIONE permette di ottenere una vasta tipologia di componenti con filettatura asportata. Le applicazioni per la formatura

VITI SENZA FINE RULLATE (WORMS) Con la rullatura si possono ottenere formature plastiche dell'acciaio per creare viti senza fine di precisione, le quali sono tipicamente accoppiate con corone dentate in applicazioni di trasmissione angolare del moto o di riduzione dello stesso. Si tratta di processi ove lo spostamento del materiale è molto elevato e pertanto è fondamentale il controllo millesimale delle grandi potenze di compressione che sono coinvolte. La generazione di rullatrici più indicata è quella a controllo numerico, in grado di gestire il cosidetto processo PSF ( precision scew forming ). La rullatura su contropunte rappresenta la soluzione tecnica più avanzata per ottenere worms con grado di precisione apprezzabile anche in applicazioni ove solitamente vengono impiegate viti senza fine ottenute per intaglio. SPLINES RULLATI ( SCANALATURA PARALLELA ) Il calettamento forzato è una forma di collegamento albero-mozzo. La scanalatura dell'albero (spline) può essere ottenuta per rullatura mediante tecnologia a cremagliera od a rulli. La scanalatura a cremagliera offre vantaggi di stabilità di processo ed altissima produttività. La scanalatura con rulli offre flessibilità dimensionale ed estrema precisione sugli evolventi. Le applicazioni per la superfinitura superficiale

La superfinitura rullata, nota anche come lappatura, può essere considerata un'ottima soluzione per ottenere finiture superficiali di parti cilindriche a bassissima rugosità. I valori di rugosità ottenibili con questo processo sono migliorativi di quelli di rettifica ed eseguibili in maniera fortemente efficiente ed economica. La sinergia ed il feedback continuo fra tornitura e successiva superfinitura rullata sono indispensabili per ottenere risultati eccellenti. Alberi, steli, viti di comando nel settore valvole sono alcune delle applicazioni tipiche di tale lavorazione. I plus Montesi nei prodotti con filettatura rullata

VITI

MADREVITI

PRODOTTI A DISEGNO E SPECIALI

AttrezzaturaRullatrici:

Rack forming rolling machine:

Utensili rullatori

TECNOLOGIE FILETTATURA RULLATAFilettatura viti di manovra a profilo trapezoidale Filettatura viti di comando/multiprincipio Filettatura viti ricircolo Raddrizzatura automatizzata Text

Perché Montesi

|

| [node:source:field_sections:0] | Il processo di rullatura e i suoi vantaggi

La rullatura è un processo di lavorazione meccanica senza asportazione di truciolo che prevede la realizzazione di filetti, formature e superfiniture superficiali attraverso il passaggio del pezzo tra utensili rullatori in rotazione continua, i quali deformano e rifiniscono la superficie esterna della materia prima fino al raggiungimento delle geometrie e dimensioni volute. La rullatura viene preferita alla tornitura ed alla molatura in quanto la deformazione plastica cui è sottoposto il pezzo comporta l’incrudimento del materiale, aumentandone la durezza e la conservazione delle sue proprietà meccaniche; inoltre, non essendo rilevabile la presenza di cricche, il prodotto rullato presenta una migliore resistenza alla fatica. Si tratta di lavorazione apprezzata in ambito aerospace (ad es. viti prive di cricche), automotive (spline su albero motore) così come nei settori del ferroviario , oil & gas, eolico e offroad (macchine per il movimento terra e agricole), anche grazie alla riduzione dei costi del prodotto. I vantaggi del processo di rullatura possono essere così riepilogati:

Le applicazioni per la filettatura

FILETTATURA DI BARRE PER OTTENIMENTO DI VITI DI MANOVRA, MOVIMENTAZIONE, VITI A RICIRCOLO DI SFERE Il processo di filettatura rullata cosiddetta "in passata" parte tipicamente dalla lavorazione di barre di acciaio le quali vengono interamente filettate. Da queste si ottengono viti delle lunghezza desiderata e lavorate nei terminali per il supporto e la trasmissione del moto. Le viti filettate con rullatura, accoppiate con madreviti a strisciamento, costituiscono un sistema di traslazione impiegato in un vasto ambito di applicazioni, sia per la manovra di carichi pesanti (viti rullate trapezoidali), sia per la movimentazione di apparati più leggeri con esigenza di maggiore velocità (viti di movimentazione). La filettatura rullata permette anche di ottenere profili per l'accoppiamento con madreviti a ricircolo di sfere. Le viti rullate per madreviti a ricircolo di sfere rappresentano una delle eccellenze delle potenzialità della filettatura rullata, laddove la precisione è raggiunta con tecnologie e processi avanzati a controllo numerico CNC. FILETTATURE RULLATE DI SEMILAVORATI Il processo di filettatura rullata cosiddetta "a tuffo" parte dalla lavorazione di componenti precedentemente torniti. L'eccellenza del risultato finale è funzione anche della qualità della fase preparatoria di tornitura, sinergia nella quale vantiamo vasto know how ed esperienza. La filettatura rullata su componenti meccanici (filetti M, Tr, WhitWorth, UNC, UNF, UNEF,) rappresenta una scelta vincolata per destinazioni speciali ( avionica) e comunque garantisce eccellenti caratteristiche di resistenza e finitura. La sinergia con i nostri reparti della divisione ASPORTAZIONE permette di ottenere una vasta tipologia di componenti con filettatura asportata. Le applicazioni per la formatura

VITI SENZA FINE RULLATE (WORMS) Con la rullatura si possono ottenere formature plastiche dell'acciaio per creare viti senza fine di precisione, le quali sono tipicamente accoppiate con corone dentate in applicazioni di trasmissione angolare del moto o di riduzione dello stesso. Si tratta di processi ove lo spostamento del materiale è molto elevato e pertanto è fondamentale il controllo millesimale delle grandi potenze di compressione che sono coinvolte. La generazione di rullatrici più indicata è quella a controllo numerico, in grado di gestire il cosidetto processo PSF ( precision scew forming ). La rullatura su contropunte rappresenta la soluzione tecnica più avanzata per ottenere worms con grado di precisione apprezzabile anche in applicazioni ove solitamente vengono impiegate viti senza fine ottenute per intaglio. SPLINES RULLATI ( SCANALATURA PARALLELA ) Il calettamento forzato è una forma di collegamento albero-mozzo. La scanalatura dell'albero (spline) può essere ottenuta per rullatura mediante tecnologia a cremagliera od a rulli. La scanalatura a cremagliera offre vantaggi di stabilità di processo ed altissima produttività. La scanalatura con rulli offre flessibilità dimensionale ed estrema precisione sugli evolventi. Le applicazioni per la superfinitura superficiale

La superfinitura rullata, nota anche come lappatura, può essere considerata un'ottima soluzione per ottenere finiture superficiali di parti cilindriche a bassissima rugosità. I valori di rugosità ottenibili con questo processo sono migliorativi di quelli di rettifica ed eseguibili in maniera fortemente efficiente ed economica. La sinergia ed il feedback continuo fra tornitura e successiva superfinitura rullata sono indispensabili per ottenere risultati eccellenti. Alberi, steli, viti di comando nel settore valvole sono alcune delle applicazioni tipiche di tale lavorazione. I plus Montesi nei prodotti con filettatura rullata

VITI

MADREVITI

PRODOTTI A DISEGNO E SPECIALI

|

| [node:source:field_sections:0:entity] | Rullatura > Sections |

| [node:source:field_sections:0:target_id] | 129 |

| [node:source:field_sections:0:target_revision_id] | 5163 |

| [node:source:field_sections:1] | AttrezzaturaRullatrici:

Rack forming rolling machine:

Utensili rullatori

|

| [node:source:field_sections:1:entity] | Rullatura > Sections |

| [node:source:field_sections:1:target_id] | 126 |

| [node:source:field_sections:1:target_revision_id] | 5164 |

| [node:source:field_sections:2] | TECNOLOGIE FILETTATURA RULLATAFilettatura viti di manovra a profilo trapezoidale Filettatura viti di comando/multiprincipio Filettatura viti ricircolo Raddrizzatura automatizzata |

| [node:source:field_sections:2:entity] | Rullatura > Sections |

| [node:source:field_sections:2:target_id] | 127 |

| [node:source:field_sections:2:target_revision_id] | 5165 |

| [node:source:summary] | <p>La tecnologia della filettatura rullata ( processo di deformazione a freddo dell'acciaio ) è stata introdotta dal fondatore Paolo Montesi all'alba degli anni '80, rappresentando all'epoca un processo "particolare e poco conosciuto" seppur sviluppato dall'industria tedesca già nei primi anni del novecento.</p> <p>Le prime rullatrici tedesche rappresentarono un apripista nell'approfondimento dei vantaggi del processo legati alla produttività ed economicità della filettatura rullata.</p> |

| [node:source:title] | Rullatura |

| [node:source:url] | https://www.montesi.it/it/rullatura |

| [node:source:url:absolute] | https://www.montesi.it/it/rullatura |

| [node:source:url:args] | , rolling |

| [node:source:url:args:count] | 1 |

| [node:source:url:args:first] | rolling |

| [node:source:url:args:join-path] | rolling |

| [node:source:url:args:last] | rolling |

| [node:source:url:args:reversed] | rolling |

| [node:source:url:brief] | www.montesi.it/it/rullatura |

| [node:source:url:path] | /rolling |

| [node:source:url:relative] | /it/rullatura |

| [node:source:url:unaliased] | https://www.montesi.it/it/node/28 |

| [node:source:url:unaliased:absolute] | https://www.montesi.it/it/node/28 |

| [node:source:url:unaliased:args] | , node, 28 |

| [node:source:url:unaliased:brief] | www.montesi.it/it/node/28 |

| [node:source:url:unaliased:path] | /node/28 |

| [node:source:url:unaliased:relative] | /it/node/28 |

| [node:url] | https://www.montesi.it/en/rolling |

| [node:url:absolute] | https://www.montesi.it/en/rolling |

| [node:url:args] | , rolling |

| [node:url:args:count] | 1 |

| [node:url:args:first] | rolling |

| [node:url:args:join-path] | rolling |

| [node:url:args:keys:count] | 1 |

| [node:url:args:last] | rolling |

| [node:url:args:reversed] | rolling |

| [node:url:args:reversed:count] | 1 |

| [node:url:args:reversed:first] | rolling |

| [node:url:args:reversed:join-path] | rolling |

| [node:url:args:reversed:last] | rolling |

| [node:url:brief] | www.montesi.it/en/rolling |

| [node:url:path] | /rolling |

| [node:url:relative] | /en/rolling |

| [node:url:unaliased] | https://www.montesi.it/en/node/28 |

| [node:url:unaliased:absolute] | https://www.montesi.it/en/node/28 |

| [node:url:unaliased:args] | , node, 28 |

| [node:url:unaliased:args:count] | 2 |

| [node:url:unaliased:args:first] | node |

| [node:url:unaliased:args:join-path] | node/28 |

| [node:url:unaliased:args:keys] | 0, 1 |

| [node:url:unaliased:args:last] | 28 |

| [node:url:unaliased:args:reversed] | 28, node |

| [node:url:unaliased:brief] | www.montesi.it/en/node/28 |

| [node:url:unaliased:path] | /node/28 |

| [node:url:unaliased:relative] | /en/node/28 |